In the realm of manufacturing PVC fiber-reinforced hoses, the extrusion process stands as a critical pillar that defines the quality, durability, and functionality of the end product. This comprehensive guide aims to demystify the intricacies of PVC fiber reinforced hose extrusion, catering to both seasoned manufacturers and enthusiasts seeking to delve into the intricacies of this production domain.

Braided Hose Pipe Application:

PVC fiber reinforced Braided Hose Pipe. This type of hose pipe is manufactured using Polyvinyl Chloride (PVC), a material that is renowned for its robustness and durability. A key characteristic of this hose pipe is the fiber reinforcement, which significantly enhances its strength and longevity.

The PVC fiber reinforced Braided Hose Pipe is versatile and caters to numerous uses across different settings and industries. From plumbing and construction to gardening and automotive industries, this pipe is valued for its flexibility, durability, and resistance to extreme conditions

Applications of reinforced PVC tubing:

- Water and fluid lines

- Food processing and Beverage line

- Chemical transfer

- Compressed air & gas

- Garden

- Construction and building sites

Equipment and Production Process for PVC Fiber Reinforced Hose Extrusion?

Producing PVC braided reinforced hoses through extrusion involves a precise combination of equipment and a well-defined production process. Below is an overview of the essential equipment and the step-by-step production process required for manufacturing PVC braided reinforced hoses.

Equipment:

- Raw Material Mixing System:

- PVC Resin: The base material for the hose.

- Plasticizers and Stabilizers: Enhance flexibility and stability.

- Reinforcement Fiber: Typically made of high-strength polyester or nylon.

- Extruder:

- The heart of the process, the extruder melts and blends the raw materials into a homogenous molten mass.

- Temperature control is crucial to achieve the desired material consistency.

- Braiding Machine:

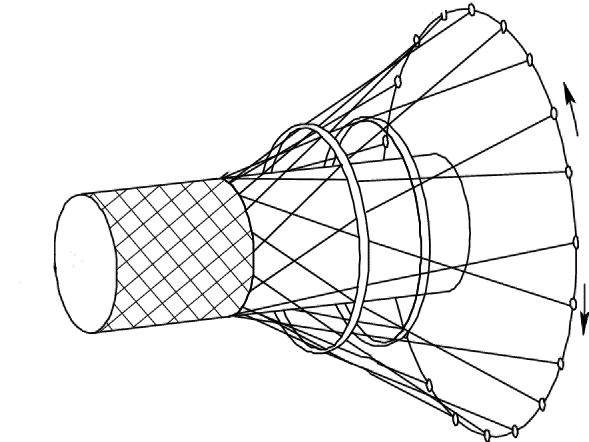

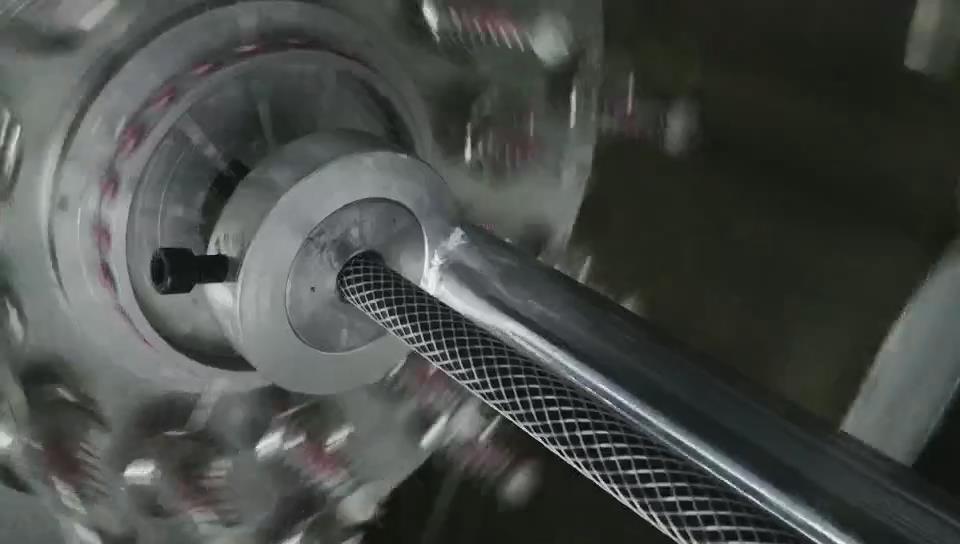

- For reinforcing the hose, a braiding machine intertwines high-strength fibers around the extruded core.

- The machine’s settings control the angle and tension of the braiding.

- Cooling System:

- A water or air cooling system is employed to rapidly cool the extruded and braided hose to solidify its structure.

- Caterpillar Haul-Off Machine:

- This equipment pulls the extruded and braided hose with controlled tension to maintain its dimensions.

- Speed adjustments are critical to prevent deformation and ensure uniformity.

- Oven or Hot Water Tank:

- The hose passes through an oven or hot water tank to undergo a curing process, enhancing its strength and durability.

- The temperature and dwell time in this stage are carefully controlled.

- Marking and Printing Machine:

- For branding and information purposes, a marking and printing machine may be used to imprint logos, specifications, or other details on the hose surface.

- Cutting Machine:

- Precision is key during the cutting stage to achieve uniform hose lengths.

- Automatic cutting machines are often employed for efficiency.

- Coiling Machine:

- The coiling machine winds the finished hoses into manageable and market-ready coils.

- It ensures neatness and convenience in handling and transportation.

Factors Affecting the Quality of PVC Fiber Reinforced Hose Extrusion?

The quality of braided hose extrusion is influenced by several factors, with the braiding machine playing a pivotal role in determining the overall excellence of the final product. The key factors affecting the quality of braided hose extrusion include:

- Braiding Tension:

- The tension applied by the braiding machine significantly impacts the structural integrity of the hose. Proper tension ensures uniform braiding, preventing weak points or irregularities in the final product.

- Braiding Angle and Pattern:

- The angle and pattern of the braiding determine the strength and flexibility of the hose. The braiding machine must be configured accurately to achieve the desired angle and pattern, ensuring optimal performance under varying conditions.

- Material Compatibility:

- The braiding machine should be compatible with the materials used in the extrusion process. Ensuring a harmonious interaction between the machine and the chosen materials is essential for achieving a cohesive and durable braided structure.

- Speed Control:

- The speed at which the braiding machine operates affects the overall quality of the extruded hose. Proper speed control prevents overstretching or irregular braiding, contributing to a consistent and high-quality end product.

- Layer Adhesion:

- The braiding machine must facilitate strong adhesion between the braided layer and the core material. Inconsistent adhesion can lead to delamination and compromise the durability of the hose.

- Material Tension Control:

- Controlling the tension of the materials during the braiding process is crucial. The braiding machine should offer precise control mechanisms to maintain consistent tension, ensuring a uniform and reliable braided structure.

- Braiding Machine Maintenance:

- Regular maintenance of the braiding machine is essential for sustained quality. Any wear and tear or malfunctions in the machine can adversely affect the braiding process, leading to defects in the final product.

- Flexibility Settings:

- Adjustable flexibility settings on the braiding machine allow manufacturers to tailor the hose to specific application requirements. The ability to customize flexibility ensures that the extruded hose meets diverse industry standards and consumer needs.

- Monitoring Systems:

- Incorporating monitoring systems into the braiding machine enhances quality control. Real-time monitoring of braiding parameters enables quick adjustments, minimizing defects and ensuring a consistently high-quality output.

In conclusion, the braiding machine stands as a critical component in the production of braided hoses through extrusion. By carefully considering and optimizing the factors mentioned above, manufacturers can elevate the quality of their braided hose extrusion process, producing hoses that meet stringent standards for durability, flexibility, and overall performance.

As we can see from the picture, the middle strengthening layer is wound with high-strength polyester fibers into diamond mesh shapes. Polyester fiber itself has strength, abrasion resistance, and elastic recovery ability; also, woven into a diamond mesh with consistent pitch, the strength, abrasion resistance, and compression resistance of the entire hose are greatly improved.

To Conclusion

In the realm of PVC fiber reinforced hose extrusion, mastering the intricacies of production is paramount to achieving excellence. As we’ve explored the technical facets of this manufacturing process, several key factors emerge that play pivotal roles in shaping the quality and performance of the final product.

The artistry of PVC fiber reinforced hose extrusion lies not only in the meticulous selection of materials but also in the adept utilization of cutting-edge technology. From the initial blending of PVC resins and reinforcement fibers to the precise control of extrusion parameters, each step contributes to the integrity of the hose. The braiding machine, as a linchpin in this process, determines the very fabric of the hose—its strength, flexibility, and overall resilience.

Factors such as braiding tension, angle, and pattern wield significant influence over the structural soundness of the hose. The delicate dance between material compatibility and tension control ensures a harmonious interplay, resulting in a braided layer that stands as a testament to durability and reliability. The importance of layer adhesion cannot be overstated, as it fortifies the hose, making it capable of withstanding the rigors of real-world applications.

Moreover, the flexibility settings and monitoring systems integrated into the braiding machine allow manufacturers to tailor hoses to diverse needs. This adaptability not only aligns with industry standards but also caters to the nuanced requirements of end-users across various applications.

In essence, PVC fiber reinforced hose extrusion is an art form guided by precision and innovation. It’s a journey where raw materials transform into reliable conduits through the harmonious orchestration of extrusion and braiding technologies. As we navigate the complexities of this process, we pave the way for hoses that transcend mere utility—they become symbols of resilience, adaptability, and the unwavering commitment to quality.

In the ever-evolving landscape of manufacturing, those who master the art of PVC fiber reinforced hose extrusion, leveraging the technical insights shared in this exploration, are poised to elevate their products to unparalleled heights. The journey doesn’t end here; it extends to a future where each hose produced is a testament to the fusion of expertise and technology, embodying the very essence of durability and performance in every unyielding fiber.

Tags:

Extrusion Process (2) PA Extrusion (1) Plastic Extruders (4) Reinforced Hose (2) Success Projects (1) TPE Extrusion (1) Troubleshooting (1)

Related Products