TPE Strips Extrusion Line

TPE Strips Extrusion Line

TPE Extrusion Machine Applications :

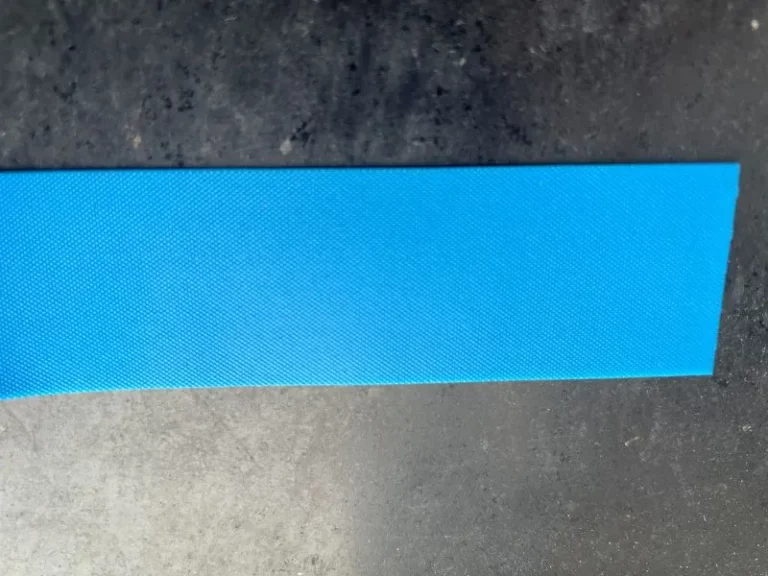

Our TPE (Thermoplastic Elastomer) strip extrusion line is specifically designed for the extrusion of strips such as tourniquets, yoga exercise bands or TPE bandages.

- TPE tourniquet

- Yoga Band

- Excerise Band

- Medical Bandage

Customization Options:

This equipment does not support customization, due to the elasticity of TPE, we do not support the customization of subsequent non-standardized automatic winder for individual customers.

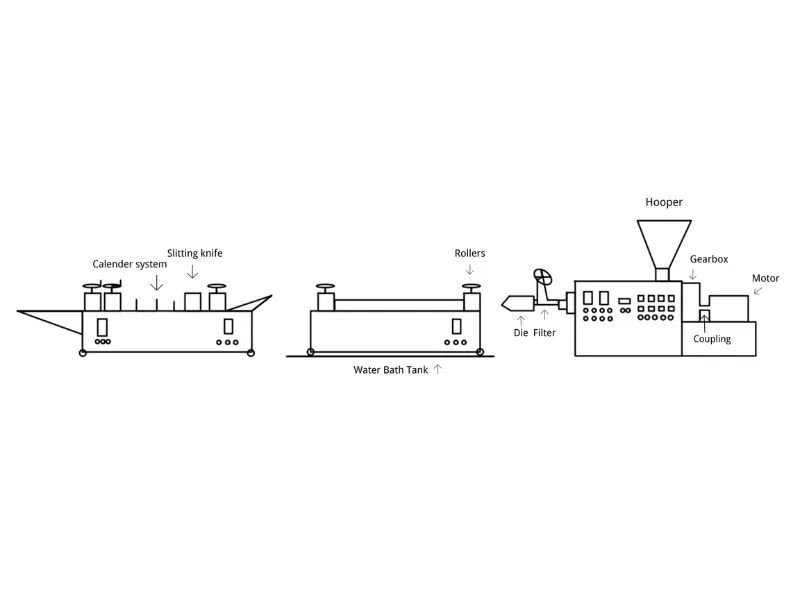

TPE extrusion machine Line Overview

This TPE extrusion equipment for strip-shaped materials was developed two years ago. With TPE becoming the mainstream material for medical tourniquets and bandages, replacing traditional rubber, the demand for this extrusion equipment has surged. Unlike most manufacturers that only produce extrusion machines, leaving customers to customize non-standardized equipment for downstream processes like roller calibration, cooling, and cutting, we collaborated with clients to develop these subsequent components. This collaboration has resulted in a comprehensive production system. Clients can customize cutting parameters such as thickness, width, and length according to their product requirements.

TPE extrusion Line Technical Specifications

Equipment included in the complete TPE extrusion machine line

Main Single Screw Extruder

This is the extrusion machine for TPE strip-shaped materials. The raw materials are melted inside the screw barrel and then extruded from here. Typically, we use a 65/30 size single screw extruder. We employ RKC temperature controllers imported from Japan to manage the temperature and solid-state relays for heating control precisely.

Two wheel calender

This section of the machine comprises a set of rollers and a water-cooled shaping trough. The rollers control the product’s thickness, width, and surface texture, creating either a smooth or textured surface. After passing through the rollers, the product enters the water trough for cooling and shaping. It is then conveyed to the cutting machine via traction.

Cutting Machine

This section is dedicated to traction and cutting. We have developed a spot-connection cutting machine in response to the primary demand for manufacturing tourniquets. This innovation ensures that the tourniquets are not completely severed during cutting but can be easily pulled apart by hand when in use. The placement of the blades is customized based on the specifications of the customer’s product sizes.

Post-production samples

FAQ about TPE extrusion

Most frequent questions and answers

The formulation of TPE materials is considered proprietary information for each supplier, and the characteristics of materials can vary significantly between suppliers. It’s essential to determine your production materials first.

TPE, an elastomer similar to rubber, possesses significant tensile and stretch properties. Using automatic coiling is challenging because it’s difficult to gauge the appropriate tension. This could result in the product being stretched even before it’s used.

Been specializing in single screw extruders for over 10 years.

Jinxin Plastic Machinery is a china extruder machine manufacturer was founded in 2012. Our core business is manufacturing single-screw extrusion equipment, including the main extruder, water tank, hau-off, and cutting or collecting components. We have many years of experience in mold design and manufacturing, as well as partnering with other suppliers to offer customized equipment solutions to our customers.

Our mission is to provide the highest quality products and services to our customers, and we take that mission very seriously. We believe that our success is directly tied to the success of our customers, and we are committed to helping them achieve their goals by providing them with the best possible equipment and support.

When you're considering adding a new set of extrusion equipment to your factory

01

Tell us the basics about your product

Please provide information about the raw material and size of the product you wish to produce. Having pictures or drawings to provide is the most intuitive. In addition, some requirements about the way the final product is collected and logo printing etc. need to be provided as well

02

discuss your project with us

We customize your equipment based on your product requirements, always taking the most professional approach. While some new clients may wonder why we don't follow their equipment specifications, it's because our expertise is built on years of experience.

03

complete the machine production

Once the equipment is completed, we ensure that each production line undergoes a thorough factory test before shipment. Additionally, we offer on-site installation of the equipment and provide training to the customer's staff on its usage.

04

Prompt after-sales service

We will have specialized export business personnel to interface with you. Provide timely and effective after-sales service. Warranty policy as well as adequate spare parts for wear and tear are provided

We are honest and reliable, providing cost-effective equipment for your factory

Our Customers Say

Our amazing Suppliers

Get A Quote

we will answer your inquiry within 24hrs via Emails with the suffix jfextruder.com.

We are always ready for all your needs.

If you have specific plastic product requirements in mind or questions about adding new equipment, don’t hesitate to reach out to us. Your needs and inquiries are our top priority. Contact us today to discuss how we can tailor our solutions to meet your unique goals

Factory

No. 31 Yuci Rd., Yuyao, Ningbo City, Zhejiang Province, China